What does EPDM stand for in roofing? EPDM stands for Ethylene Propylene Diene Monomer. Find out more about the popular roofing material referred to as EPDM for short.

What is EPDM?

Ethylene Propylene Diene Monomer, or EPDM for short, is a kind of synthetic rubber.

This material is typically used for roofing and window and door seals, as the membrane of EDPM rubber forms a weathertight and airtight seal, making it suitable for lengthy outside use in various weather and temperature conditions.

The synthetic rubbers' resilience to harsh weather conditions has made them a favourite for tradesmen, architects, building owners and contractors alike.

EPDM rubber comes in a number of shapes and sizes, including self gluing backs, EPDM membrane, paint or pre-moulded EPDM; this versatility allows it to be used for almost any job over all other products.

What Does EPDM Stand For?

As mentioned above, EPDM stands for ethylene propylene diene monomer; this name states its three core ingredients: ethylene, propylene and diene.

Various proportions of the chemicals are mixed to form synthetic rubber. Generally, the ethylene content is around 50%, whilst the propylene content is between 45% and 75%, and the diene is least seen with a small amount used to link the other chemicals together.

The molecular mesh created by the element diene gives the EPDM rubber its incredible flexibility, resilience and durability.

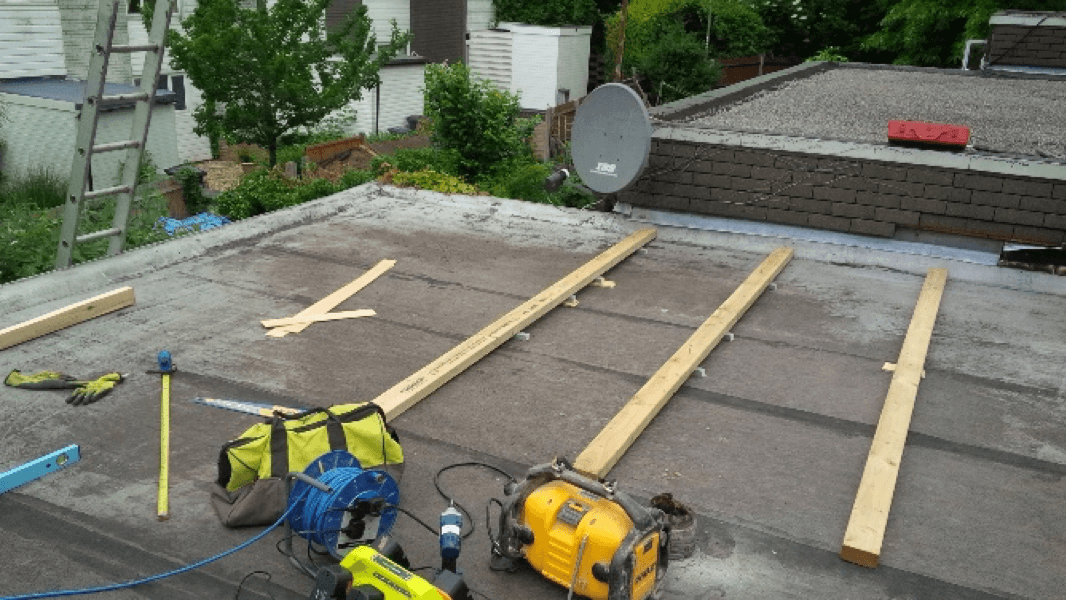

What is EPDM Roofing?

An assortment of roofing systems falls under EPDM rubber roofing. The systems generally consist of a single layer of EPDM rubber membrane and varying thermal insulation and vapour barriers.

Additional accessories are included in these systems, including pipes, drainage and gravel guards. Or, for garden roofs, there may be vegetation.

The rubber material can be used for all kinds of roofing demands; however, it's renowned for working amazingly on flatter, low-pitched roofs owed to its resilience against weathering.

EPDM rubber sheets also ease roofing tasks with a consistent application and an even layer of thickness spread over the entire roof space.

Although all other elastomers are tear-resistant and have high tensile strength, EPDM rubber is set apart by its undeniable resilience to extreme weather conditions. EPDM rubber is most suitable for roofing as it can withstand anything thrown at it by the environment, from UV rays to extreme cold.

Properties of EPDM Rubber

Widely used EPDM rubber is one of the most durable and flexible materials available for roofing jobs.

Not only does EPDM rubber have great durability against harsh weather conditions, but it also has the ability to flex into any shape to cover the dips and bends of roofs, making it an excellent insulator.

The material is impressively windproof and waterproof, as well as UV and cold & heat-resistant, making it a great option in every environment.

Moreover, it has amazing noise reduction abilities, as an elastomer it prevents vibrations from passing through it, meaning noise is blocked from exiting the room or home.

These properties make EPDM rubber act as one big, strong seal over the top of your property, stopping anything from penetrating it.

Another benefit of using EPDM rubber roofing is its strong resistance to Ozone gas. Ozone is a toxic, unstable, colourless gas that naturally occurs in small amounts in the atmosphere. It has the ability to disintegrate rubber materials easily, however, it cannot do this to EPDM.

Thanks to the diene's pendant structure, EPDM rubber is 100 to 1000 times more resistant than natural rubber regarding Ozone damage. This further encourages the use of EPDM rubber roofing.

Long-term performance of EPDM Roofing

EPDM roofing is incredibly popular owed to the material's durability and versatility. The rubber is known to withstand great temperatures (hot and cold), but how long can it really last in these conditions?

Well, a recently completed long-term study exhibits that EPDM rubber continues to perform to a high standard even after 30 years.

The study of EPDM's long-term performance capacity used state-of-the-art equipment and techniques to provide trusted tangible proof of the rubber's strength. Some key points from the study are noted below;

- After three decades of use, the samples were performing like new!

- Numerous climates were tested, and EPDM can withstand almost anything

- When EPDM systems are designed, installed and maintained correctly, the rubber can withstand extreme weather cycles

- Various indications suggest EPDM can last up to and potentially above 40 years of use.

During the study, five roofing systems were examined, each between 28-32 years of service.

It was concluded that all of the systems tested were essentially performing 'like new', as physical characteristics were just above or below the minimum properties of the recently developed 45-mil EPDM membrane, showing the longevity of EPDM rubber as a roofing material.

Firstly, roofs were inspected to check the condition of the EPDM, samples were then sent to 'Momentum Technologies' to be tested. Five important components of the rubber were tested;

1. Elongation Tensility

2.Thickness

3. Factory Seam Strength

Four other long-term performance of EPDM rubber roofing studies completed since the 1980s, and each shows similar findings.

A pattern emerged from various studies data representing EPDM's incredible longevity. With modern techniques and maintenance, the material can be expected to last up to or even exceed a 40-year service life.

Are you looking for a flat roof specialist in Andover, Basingstoke or Winchester?

If you find yourself in need of a replacement flat roof, don't hesitate to contact Flat Roofers Basingstoke today! We have staff on hand to answer any questions you might have.