Are you asking if GRP the same as fibreglass? We look at the properties of GRP roofing and explore what is fibreglass roofing. Flat Roofers Basingstoke provide GRP fibreglass roofing for Andover, Basingstoke, Winchester and the surrounding areas.

At first glance, one might assume that GRP, also known as glass-reinforced plastic, is identical to fibreglass. However, upon closer inspection, the answer is not so straightforward. While closely related, there are subtle distinctions between the two, which can lead to some confusion.

A quick internet search reveals minor differences between fibreglass and GRP, adding to the complexity. Additionally, the term FRP may further perplex the matter.

For newcomers, navigating this alphabet soup of GRP, FRP, and fibreglass can be bewildering. But fear not, understanding the relationship between these materials can help clarify the situation.

In essence, both fibreglass and GRP fall under composite materials, specifically fibre-reinforced polymers (FRPs). They combine glass fibres with a polymer matrix, commonly using polyester resin, to offer strength and durability.

Fibreglass primarily consists of glass fibres and is favoured for its high strength-to-weight ratio and durability in various applications. On the other hand, GRP is essentially the same material as fibreglass, with the term "GRP" commonly used in the UK, while "fibreglass" prevails in other regions.

What is fibreglass ?

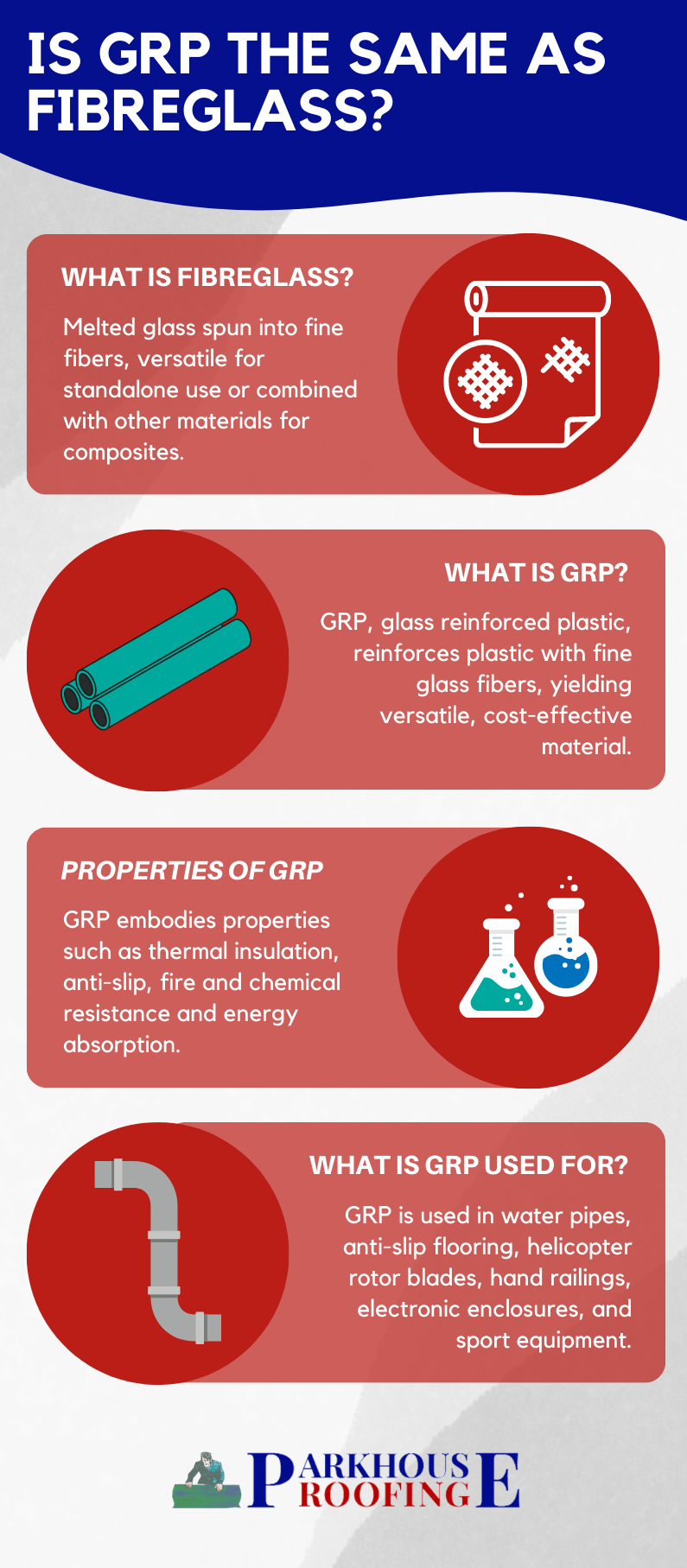

Fibreglass is a versatile material obtained by spinning melted glass into fine fibres. These glass fibres can be used alone or, more commonly, combined with other materials to form a composite.

This integration of fibres with another material results in a superior product, with enhanced strength and tailored characteristics suitable for specific purposes. Common combinations involve blending glass fibres with plastics, metals, or ceramics.

Although the end product is often referred to as 'fibreglass,' it is essential to note that this term may not be entirely accurate. If plastic is used with the fibres, the correct designation is glass-reinforced plastic, or GRP.

GRP offers remarkable properties, making it sought after for numerous applications. Its high strength-to-weight ratio and durability make it ideal for various industries, including construction, automotive, marine, and aerospace.

What is GRP?

GRP, or glass reinforced plastic, is a specific type of fibreglass. It involves reinforcing plastic with fine glass fibres, resulting in a versatile and cost-effective material suitable for various products and applications.

FRP, on the other hand, stands for fibre reinforced polymer, encompassing materials like GRP. It denotes composites formed by combining a polymer matrix with reinforcing fibres, such as glass or carbon.

GRP's exceptional strength-to-weight ratio and durability make it a popular choice in the construction, automotive, marine, and aerospace industries. In summary, GRP is a remarkable fibreglass variant, part of the broader category known as FRP.

What is FPR?

FRP, which stands for fibre reinforced polymer, is an advanced form of fibreglass. In this context, 'polymers' refer to materials composed of long chains of molecules. These polymers can be either natural, like rubber, or synthetic, and they can be strengthened by incorporating various types of fibres to enhance the characteristics of the final product.

Glass fibres are commonly used in FRP, which brings us back to GRP (glass reinforced plastic). However, FRP is not limited to glass fibres alone; it can also include carbon or graphite fibres, among others.

In essence, all FRP materials incorporate fibres. If the reinforcing fibres are glass, then it is classified as glass reinforced plastic or GRP. While all GRP is considered an FRP, not all FRP materials fall under the category of GRP. The versatility of FRP allows for a diverse range of applications, making it a sought-after material in various industries.

What Is GRP Made Of?

GRP, an abbreviation for glass-reinforced plastic, boasts a composition derived from fine strands of glass, known as fibres. These glass fibres are intricately woven together, forming a flexible and resilient fabric. The manufacturing process involves moulding the GRP to perfectly fit the desired item or structure, shaping it meticulously.

A distinguishing aspect of GRP composite is the incorporation of an aluminium oxide aggregate surface, renowned for its diamond-hard properties. This exceptional addition significantly enhances the material's ability to resist wear and tear over extended periods, making it highly durable and reliable for various applications.

The ingenious combination of glass fibres and the reinforced polymer matrix grants GRP its outstanding properties, such as a remarkable strength-to-weight ratio and exceptional resistance to corrosion and environmental factors. As a result, GRP finds extensive use in diverse industries, including construction, marine, automotive, aerospace, and many more.

Due to its unique characteristics, GRP has become a preferred choice for manufacturing an array of products, ranging from pipes, tanks, and cladding to boat hulls, automotive parts, and architectural elements. The material's versatility, durability, and longevity have solidified its position as a key player in modern engineering and design.

What Are the Properties of GRP?

GRP, also known as glass reinforced plastic, possesses a wide range of valuable properties, making it an extremely useful material in industries across the globe. These properties contribute to its widespread applicability and include the following:

Thermal Insulation: GRP exhibits excellent thermal insulation properties, making it well-suited for applications requiring temperature control.

Anti-Slip Safety: Its textured surface provides anti-slip characteristics, making GRP an ideal choice for areas where safety is of utmost importance.

High Strength-to-Weight Ratio: GRP boasts a remarkable strength-to-weight ratio, ensuring structural robustness without adding excessive weight.

Fire Resistance: While GRP does not melt like some materials, it can be produced to be fire retardant if necessary, offering enhanced fire safety.

High Energy Absorption: GRP can effectively absorb impact energy, making it suitable for applications where impact resistance is vital.

Chemical Resistance: GRP displays excellent resistance to various chemicals, making it suitable for use in corrosive environments.

Corrosion Resistance: Its inherent resistance to corrosion ensures the durability and longevity of GRP products, even in harsh conditions.

Enclosed Electrical Spaces: Due to its non-conductive nature, GRP can be safely used in enclosed electrical spaces.

Heat and Sound Insulation: GRP provides good insulation properties for both heat and sound, enhancing comfort and safety in various applications.

Easy to Shape: The flexibility of GRP allows it to be easily moulded into various shapes, accommodating diverse design requirements.

What Is GRP Used For?

GRP, or glass reinforced plastic, is a highly versatile material with numerous applications across various industries. Many products, either partially or entirely composed of GRP, find utility in different sectors. Some notable examples include the following:

- Water Pipes or Drain Coverings: Due to its durability and resistance to corrosion, GRP is an ideal choice for manufacturing water pipes and drain coverings, ensuring the longevity and reliability of such infrastructure.

- Anti-Slip Protection for Flooring: The anti-slip properties of GRP make it suitable for retrofitting dry and wet flooring, enhancing safety in diverse environments.

- Helicopter Rotor Blades and Wind Turbine Blades: GRP's high strength-to-weight ratio makes it a preferred material for fabricating rotor blades used in helicopters and wind turbines, contributing to efficient and sustainable energy production.

- Handrailing's: In various industrial and public settings, GRP handrailing's are favoured for their combination of strength and resistance to corrosion.

- Electronic Enclosures: Thanks to its non-conductive properties, GRP serves as an excellent material for electronic enclosures, ensuring the protection of sensitive equipment.

- Safety Grating in Industrial and Public Areas: GRP's anti-slip characteristics and corrosion resistance make it well-suited for safety grating applications in both industrial and public spaces.

- Sporting Equipment such as Kayaks: Sporting equipment like kayaks benefits from GRP's lightweight yet robust nature, contributing to the creation of high-performance and durable products.

Are you looking for a GRP Fibreglass Roofing specialist in Andover, Basingstoke or Winchester? Our company provides GRP Fibreglass Roofing installations throughout Andover, Basingstoke and Winchester.

Don't hesitate to contact Flat Roofers Basingstoke today! We have staff on hand to answer any questions you might have.